Understanding Powder Coating: An Overview

What is Powder Coating?

Powder coating is a method of applying a protective and decorative finish to various types of materials, primarily metals. This process involves the electrostatic application of powdered paint, which is then cured under heat to form a tough, durable shell. Unlike traditional liquid painting, which relies on solvents, powder coating utilizes finely ground particles that are heated and electrostatically charged, allowing for a uniform application that prevents drips and runs. This advanced technique results in a finish that not only enhances aesthetics but also provides superior protection against wear, corrosion, and other environmental factors.

Benefits of Powder Coating over Traditional Painting

There are numerous advantages to choosing powder coating over traditional liquid paint:

- Durability: Powder-coated surfaces are more resistant to scratches, chipping, fading, and wearing compared to painted surfaces, making them ideal for a variety of applications.

- Eco-friendliness: Powder coating contains no solvents and emits minimal volatile organic compounds (VOCs), making it a more environmentally responsible option.

- Versatile Finishes: With a wide range of colors, textures, and finishes available, powder coating can be tailored to meet specific aesthetic preferences.

- Cost-Effectiveness: Though the initial investment may be slightly higher, the longevity and durability of powder coating translate into lower replacement and maintenance costs over time.

- Quick Application: The curing process is relatively quick, often allowing for greater production efficiency than traditional painting methods.

Applications of Powder Coating in Birmingham

Powder coating is widely utilized across various industries in Birmingham, showcasing its versatility and effectiveness. Some notable applications include:

- Automotive Industry: From car frames to wheels, automotive components benefit from the protective and aesthetic properties of powder coating.

- Home Furnishings: Powder coating is used for patio furniture, lighting fixtures, and appliances, enhancing appearance and longevity.

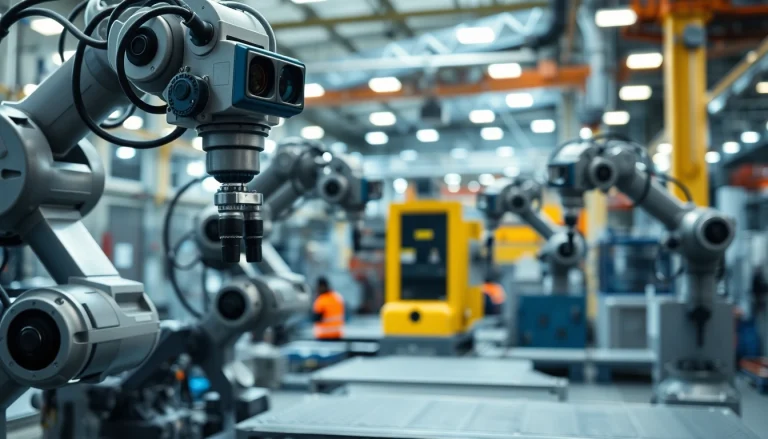

- Industrial Equipment: Components such as conveyor belts, machinery parts, and handrails often undergo powder coating to withstand harsh operating conditions.

- Architectural Elements: Fences, railings, and architectural features receive a durable finish to combat weathering and mechanical wear.

Choosing the Right Powder Coating Service in Birmingham

Factors to Consider When Selecting a Provider

When searching for a reliable powder coating Birmingham service, several key factors should be considered to ensure quality and satisfaction:

- Experience: Look for service providers with extensive industry experience and a solid reputation for high-quality work.

- Certifications: Ensure that the company has appropriate certifications and adheres to industry standards.

- Services Offered: Determine whether they offer a range of powder coating services or specialize in certain applications.

- Quality Control: Inquire about their quality assurance processes to ensure the finished product meets expectations.

- Turnaround Times: Evaluate the company’s efficiency and ability to meet deadlines, particularly for larger projects.

Top Powder Coating Companies in Birmingham

When considering providers, here are some top-rated powder coating companies in Birmingham:

- Coyote Coating: Known for custom powder coating solutions, they cater to various client needs, from automotive parts to decorative features.

- Pablo’s Custom Powder Coating: With an established presence in the Birmingham area since 2005, they offer a range of powder coating services tailored to various industries.

- Steel City Metal: Specializing in powder coating and sandblasting services, they serve a diverse clientele, ensuring high-quality finishes on their products.

- Performance Powder Coatings: Renowned for their attention to detail and customer service, they provide tailored powder coating solutions across Birmingham.

Customer Reviews and Testimonials

Reading customer testimonials can provide valuable insights into the quality of service offered by powder coating companies. Look for reviews that mention:

- The durability of the finish.

- Timeliness and efficiency of service.

- Overall customer satisfaction.

- Responsiveness to inquiries and support during the coating process.

The Powder Coating Process Explained

Preparation: Cleaning and Pre-Treatment

The initial stage of the powder coating process is crucial for ensuring a successful application. This step includes several critical actions:

- Cleaning: The surfaces to be coated must be thoroughly cleaned of contaminants such as oil, grease, rust, and dirt. This is typically done using various cleaning methods, including abrasive blasting or chemical washes.

- Pre-Treatment: Following cleaning, a pre-treatment process is often employed, which may involve phosphating or chromating. This enhances adhesion of the powder to the substrate and improves corrosion resistance.

Application Techniques for a Flawless Finish

Once prepared, the application of the powder coat begins. This can be executed through various methods:

- Electrostatic Spraying: The most common method, where powder particles are electrically charged and sprayed onto the grounded surface.

- Fluidized Bed Coating: This involves submerging the preheated component into a bed of fluidized powder, resulting in an even coating.

- Airless Spray: Utilizes high pressure to atomize the powder and deliver it to the substrate, suitable for larger and less complex shapes.

Curing: Importance of Proper Techniques

After application, the coated items must undergo curing, which solidifies the powder into a durable layer. The curing process generally involves:

- Heating: The coated items are placed in an oven where temperatures typically reach between 350°F to 400°F (about 177°C to 204°C), depending on the powder used.

- Duration: Curing times can vary from 10 to 30 minutes, based on the thickness of the powder layer and the specific powder formulation.

- Cooling: Proper cooling is necessary to ensure that the coating adheres correctly and develops maximum durability.

Costs and Pricing for Powder Coating in Birmingham

Average Costs for Different Services

The costs associated with powder coating can vary significantly based on several factors, including the size of the item, the type of powder used, and the complexity of the job. On average, powder coating services range from $50 to $430 per item, with typical customer expenditures averaging around $170. Factors such as:

- The size and shape of the item.

- The number of colors or coatings required.

- Additional services, such as surface preparation or repair.

Understanding Factors Affecting Pricing

Several critical factors can influence the cost of powder coating, including:

- Material Type: Different materials may require specific pre-treatment processes or powders, affecting overall pricing.

- Quantity: Larger orders often qualify for bulk pricing, reducing the per-item cost.

- Complexity: More intricate designs may necessitate specialized techniques, leading to higher costs.

- Location: The region’s market rates can impact service prices significantly.

Getting Quotes: What to Ask

When soliciting quotes from powder coating providers, consider asking the following crucial questions:

- What is included in your pricing? (e.g., cleaning, pre-treatment, curing)

- What types of powder do you use, and what are their properties?

- Can you provide references or examples of your previous work?

- What are your anticipated turnaround times?

- Do you offer any guarantees or warranties on your work?

Maintaining Your Powder Coated Products

Best Practices for Longevity

To ensure the longevity of your powder-coated items, adopting preventive maintenance practices is essential:

- Avoid Harsh Chemicals: Clean surfaces with mild detergents and avoid abrasive cleaners that can damage the finish.

- Regular Inspections: Check for chips or scratches that may expose the substrate, addressing them promptly to prevent corrosion.

- Environmental Considerations: Try to keep powder-coated items sheltered from extreme weather conditions to mitigate deterioration.

How to Clean and Care for Powder Coated Items

Regular cleaning is crucial to maintaining the appearance and integrity of powder-coated items. Recommended cleaning steps include:

- Using a soft cloth or sponge with warm, soapy water for routine cleaning.

- Avoiding abrasive pads or solvents that could damage the coating.

- Rinsing thoroughly to ensure no soap residue remains.

Common Issues and How to Diagnose

While powder-coated finishes are generally durable, issues can arise. Common problems include:

- Chipping: Often occurs due to impacts; addressing the source of the impacts can prevent further damage.

- Fading: Caused by prolonged exposure to UV rays; applying UV-resistant coatings can help reduce fading.

- Corrosion: Typically results from substrate exposure; ensuring good surface preparation can mitigate this issue.