Understanding Liquid Packaging Machines

In the fast-paced world of manufacturing and distribution, the efficiency and effectiveness of packaging can make or break an operation. Liquid packaging machines play a critical role in ensuring that products are filled, sealed, and ready for distribution swiftly and securely. As businesses across various sectors, including food and beverage, pharmaceuticals, and chemicals, seek to optimize their processes and enhance productivity, the importance of partnering with a reliable Liquid Packaging Machine Supplier cannot be overstated.

Types of Liquid Packaging Machines

Understanding the different types of liquid packaging machines is essential for selecting the right one for your business needs. Here are some common types:

- Filling Machines: These machines fill a container with the desired liquid. They can be gravity fillers, overflow fillers, or pressure fillers, depending on the liquid viscosity and the required accuracy.

- Capping Machines: After filling, capping machines secure the cap on containers to ensure that the product remains sealed during transport and storage.

- Labeling Machines: These machines apply labels to bottles or boxes. Proper labeling is crucial for brand recognition and regulatory compliance.

- Sealing Machines: Used to seal containers with lids or films, sealing machines help maintain product freshness and extend shelf life.

- Complete Lines: Integrated systems that combine filling, capping, and labeling processes into one continuous operation, enhancing efficiency.

Key Features to Consider

When choosing a liquid packaging machine, key features should be taken into account:

- Speed: The speed of the machine should match your production needs; high-speed machines are ideal for businesses with high output demands.

- Accuracy: Precision in filling is vital, especially for liquid products where overfilling or underfilling can result in significant financial losses and consumer dissatisfaction.

- Ease of Use: Machines should be user-friendly with intuitive controls, facilitating quick operator training.

- Durability: The materials used in the construction of the machines need to be robust to withstand continuous operation and minimize maintenance costs.

- Flexibility: The ability to handle different bottle types, sizes, and liquid viscosities can enhance overall operational efficiency.

Common Applications in Various Industries

Liquid packaging machines are utilized across many industries due to their versatility. Here are some applications:

- Food and Beverage: Packaging juices, sauces, dairy products, and more with machines capable of handling various viscosities.

- Pharmaceuticals: Ensuring accurate dosing and compliance with hygiene standards when packaging medicated liquids.

- Cosmetics: Filling products like shampoos, lotions, and fragrances in diverse container formats.

- Chemicals: Handling industrial liquids, ensuring safety standards and equipment robustness for harsh materials.

Advantages of Choosing a Reliable Supplier

Selecting the right supplier for liquid packaging machines can enhance your operation in several ways. Here are the advantages of choosing a reliable supplier:

High-Quality Manufacturing Standards

When partnering with a reputable supplier, you can expect high manufacturing standards that prioritize safety, efficiency, and durability. This includes using quality materials and adhering to industry standards. A supplier that invests in advanced technology ensures that their machines are reliable over long periods of use, minimizing downtime and maintenance costs.

After-Sales Support and Service

Reliable suppliers offer robust after-sales support, including installation, training, and maintenance services. Should any issues arise, having access to knowledgeable support staff who can quickly address problems can save your business from costly delays. This ongoing relationship is crucial for enhancing operational efficiency.

Customization Options for Your Packaging Needs

Every business has unique requirements. A good supplier provides customization options tailored to your specific needs, from filling volumes to machine sizes and functionalities. This ensures that your liquid packaging operations align with your production goals, making the process more streamlined.

How to Select the Right Machine for Your Business

Choosing the right liquid packaging machine involves understanding your operational needs, budget, and growth objectives. Here’s a guide on how to approach this decision:

Assessing Production Volume Needs

Determining your production volume is the first step in selecting a liquid packaging machine. Analyze your current production rates and future growth expectations. Machines are available in various capacities, so choose one that meets current needs while allowing for expansion without requiring an immediate replacement.

Evaluating Machine Versatility

While some machines specialize in specific liquids or bottle types, opting for versatile machines can maximize operational efficiency. Consider machines capable of handling different bottle shapes, sizes, and liquid types if your product range is diverse.

Budgeting for Liquid Packaging Solutions

Budget considerations are paramount in decision-making. Beyond initial purchase costs, factor in installation, maintenance, potential upgrades, and operational costs. Investing in a slightly more expensive but high-quality machine can lead to lower operational costs and higher profitability in the long term.

Emerging Trends in Liquid Packaging Technology

As technology evolves, so do the trends in liquid packaging. Understanding these can help businesses remain competitive. Here are some of the emerging trends:

Sustainability in Packaging Materials

More companies are recognizing the importance of sustainable packaging. Innovations in eco-friendly materials, including biodegradable plastics and recyclable materials, are becoming standard. Consumers increasingly prefer products with minimal environmental impact, making sustainable packaging a critical aspect of business strategy.

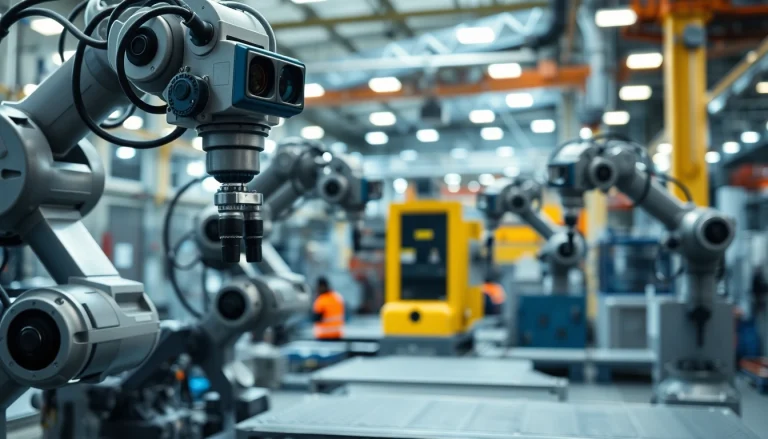

Automation and Smart Technologies

The move towards automation continues to grow, with advancements in IoT (Internet of Things) integrating smart technologies into liquid packaging systems. These systems provide real-time data, enabling manufacturers to optimize production lines, minimize waste, and predict maintenance needs, ultimately leading to enhanced efficiency.

Consumer Preferences Shaping Packaging Designs

As consumer preferences evolve, so too must packaging designs. Brands are leveraging packaging as a marketing tool, focusing on aesthetics while ensuring functionality. Attractive designs that stand out on shelves can significantly impact buying decisions, while the ease of use remains a priority.

Success Stories: Businesses Thriving with Quality Machines

Numerous businesses have effectively harnessed the capabilities of quality liquid packaging machines to enhance their operations. Here are a few success stories:

Case Study: Food Industry Innovators

A leading juice manufacturer underwent a significant transition by adopting a high-speed liquid packaging machine that enabled rapid filling and sealing. Their output doubled within six months, reducing labor costs and increasing profitability. Moreover, with a quicker turnaround, they improved their market responsiveness and customer satisfaction rates.

Transforming Pharmaceutical Packaging

A pharmaceutical company specializing in liquid medications faced challenges regarding inconsistencies in dosing. By integrating an advanced liquid filling machine with accuracy calibration, they minimized discrepancies in volume. Their production received quality assurance certifications, while customer trust significantly increased.

Boosting Efficiency in Chemical Production

A chemical company shifted to automated liquid packaging solutions aimed at hazardous materials. The introduction of robust capping and sealing machines reduced spillage and enhanced plant safety. Additionally, compliance with stringent health and safety regulations improved, allowing them to enter previously inaccessible markets.