Understanding Air Compressors

What are Air Compressors?

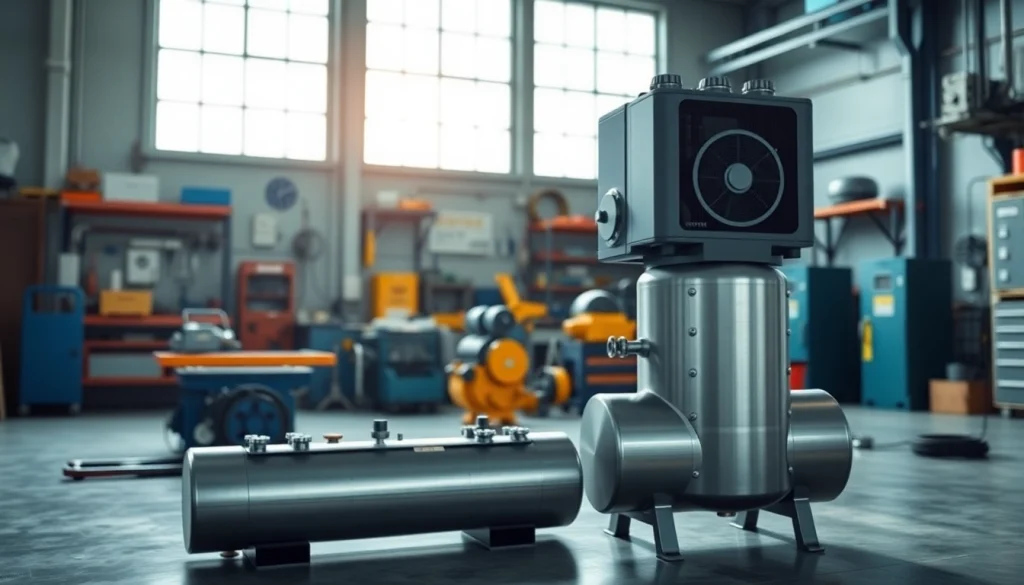

Air compressors are mechanical devices used to convert power into potential energy stored in pressurized air. The process typically involves drawing atmospheric air into a chamber, where it is compressed, subsequently increasing its pressure. This compressed air can be utilized for a range of applications, from powering tools to inflating tires or even operating systems in large-scale industrial settings. The essence of air compressors lies in their ability to enhance the availability and usability of air, providing crucial functionality in numerous sectors.

Types of Air Compressors Available

In the market, various types of air compressors cater to different needs. The primary classifications include:

- Reciprocating Air Compressors: These are commonly used in small to medium-sized applications. They utilize a piston mechanism to compress air and are favored for their simplicity and affordability.

- Rotary Screw Air Compressors: Known for their efficiency in large-scale applications, rotary compressors use twin rotors to compress air continuously. They are ideal for industrial applications that require high volumes of compressed air.

- Scroll Compressors: These compressors are less common but are valued for their quiet operation and reliability. They use a pair of spiral scrolls to compress air, making them suitable for HVAC systems and refrigeration.

- Centrifugal Compressors: Typically used in very large-scale operations, these compressors work by using a rotating disc to impart velocity to the air, which is then captured in a high-pressure casing.

Applications of Air Compressors in Various Industries

Air compressors serve a broad spectrum of applications across different industries. Some prominent uses include:

- Manufacturing: In production lines, air compressors are vital for powering pneumatic tools, operating machinery, and providing essential energy for various processes.

- Construction: They are employed for powering various tools such as nail guns, jackhammers, and paint sprayers, significantly enhancing task efficiency.

- Aerospace: Air compressors are crucial in aircraft maintenance tasks, including engine testing and instruments calibration.

- Food and Beverage: In this industry, compressors help in various processes such as packaging, bottle filling, and maintaining sanitary conditions.

- Healthcare: Medical air compressors are used in respiratory therapy, anesthesia delivery, and dental applications among others.

Choosing the Right Air Compressor Supplier in Saudi Arabia

Criteria for Selecting a Reliable Supplier

When searching for an air compressor supplier in Saudi Arabia, several key criteria should guide your decision:

- Reputation: Look for suppliers with strong market presence and positive reviews from previous clients.

- Quality of Equipment: Assess whether the supplier’s products meet the quality standards needed for your specific applications.

- Support and Service: Consider the availability of after-sales services, including maintenance, warranty terms, and customer support.

- Range of Products: Choose suppliers offering a broad range of air compressors and related accessories to cater to diverse requirements.

- Pricing: While it’s important to stay within budget, the cheapest option isn’t always the best. Compare different suppliers on value and service, not just price.

Comparing Local vs. International Suppliers

When selecting an air compressor supplier, businesses often face the choice between local and international suppliers. Each option has its merits:

Local Suppliers:

- Familiarity with Market Needs: Local suppliers often understand regional demands and offer products specifically tailored to local businesses.

- Proximity: Local suppliers can provide faster delivery times and may offer more immediate support or maintenance services.

- Cost-Effective Logistics: Transportation costs are often lower, making it more economical to source from local suppliers.

International Suppliers:

- Access to Advanced Technology: Many international suppliers offer cutting-edge technology and unmatched product quality.

- Broader Product Range: Global suppliers may provide a wider variety of air compressors, allowing companies to find exactly what they need.

- Brand Reputation: Established international brands often come with proven reliability and performance-backed guarantees.

Industry-Specific Suppliers in Saudi Arabia

Finding the right supplier may also vary depending on industry requirements. Specialized suppliers can offer tailored solutions that meet the unique needs of different sectors:

- Construction Industry: Look for suppliers offering durable and portable air compressors that can withstand the rigors of construction sites.

- Manufacturing Sector: Suppliers that provide heavy-duty compressors equipped with energy-efficient features are essential in manufacturing.

- Healthcare Providers: Medical-grade air compressors demand strict adherence to safety and performance standards, necessitating suppliers with informed expertise.

Benefits of Using Quality Air Compressors

Improving Efficiency and Productivity

Using high-quality air compressors can significantly boost operational efficiency. Efficient compressors minimize downtime, allowing for continuous operations and quick recovery times. With reliable air supply, workers can utilize tools and equipment without interruptions, thereby enhancing overall productivity.

Reducing Operational Costs

Investing in quality air compressors often results in long-term savings. While the initial cost may be higher than sub-par options, the durability and energy efficiency of quality compressors prevent costly breakdowns and inefficient operation. Additionally, quality compressors usually have lower maintenance costs, further reducing operational expenses.

Ensuring Longevity and Performance

Quality air compressors are engineered for longevity, featuring robust construction and advanced components. By utilizing materials that withstand wear and tear, high-grade compressors ensure sustained performance and reliability over time, which is particularly crucial in demanding environments.

Trends in the Air Compressor Market in Saudi Arabia

Technological Innovations in Air Compressors

The air compressor industry is evolving, with technological advancements driving efficiency and performance enhancements. Innovations such as variable speed drives, IoT connectivity, and advanced control systems are becoming standard, allowing for smarter air systems that optimize energy use and productivity.

Market Demand and Growth Opportunities

Saudi Arabia’s growing industrial sector presents ample opportunities for air compressor suppliers. With economic diversification initiatives, including Vision 2030, demand for efficient, reliable, and sustainable compressors is on the rise. Suppliers can leverage this growing market by aligning their offerings with industry needs and sustainability goals.

Environmental Considerations and Sustainability

As global awareness of environmental issues increases, suppliers in Saudi Arabia are beginning to focus on providing energy-efficient and eco-friendly air compressors. Implementing technologies that reduce emissions and improve energy consumption is not just advantageous for the environment; it’s increasingly becoming a requirement as industries move towards sustainability.

How to Maintain Your Air Compressors

Routine Maintenance Practices

Proper maintenance is essential for ensuring the longevity and efficiency of air compressors. Routine practices should include regular inspections, filter changes, oil checks, and draining moisture from the system. Developing a structured maintenance schedule helps prevent unexpected breakdowns and enhances performance.

Recognizing Common Issues

Common issues that affect air compressor performance include noise abnormalities, oil leaks, and pressure drops. Early identification of these issues often prevents more significant problems down the line. Employees should be trained to monitor performance indicators and understand what to look for in terms of functionality.

When to Call Professional Support

While routine maintenance can often be conducted in-house, there are situations where professional support is necessary. If an air compressor experiences substantial drop in efficiency, persistent leaks, or abnormal sounds, it is wise to consult with a certified technician. Regular professional assessments also ensure that the compressor maintains peak performance.